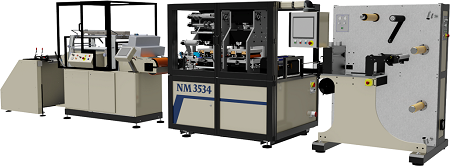

NM Converting system

Newfoil NM Converting System

The Newfoil NM converting system has been developed as a flexible platform for the conversion of high quality label stock, pre-printed on either digital or conventional printing equipment.

This machine has a maximum web width of 340mm flat screen and flexo printing units can be incorporated in-line with the servo driven hot foil stamping and embossing stations.

Important Characteristics:

: 340mm web width

: up to 18,000 impressions per hour (stamping/die-cut stations)

: Heavy-duty unwind with an 800mm diameter roll capacity

: Flatbed screen unit (optional)

: Rotary flexo unit (optional)

: Hot foil stamping and die-cutting units (number of stations flexible to customers’ specification)

: Rewind and finishing unit with finished label and matrix rewinds (500mm diameter roll capacity)

The NM range can be tailored to best suit your production requirements, including the application of high quality embellishments demanded by todays label market.

The options available include:

: Spot varnishing

: tactile varnishing

: Hot foil stamping

: Embossing

: Combination embossing

: Micro embossing

: Variable data and bar code printing

: Hologram printing

: RFID insertion

: Web slitting

: Sheeting, Conveyor and Stacking

: Pneumatic punch tools

The NM system features many unique innovations, introduced to make offline finishing and converting quicker, simpler and more cost-effective than in-line systems.

Being essentially an engineering based company meeting the criteria for special design projects is standard procedure.

If you would like more information on this product, please Contact Us

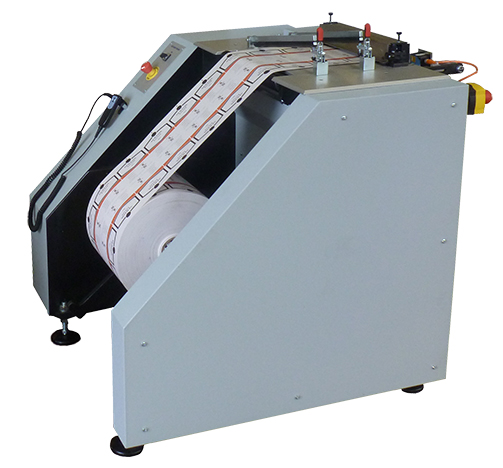

Newfoil Heavy Duty Unwind

A Heavy duty unwind unit, capable of handling large, heavy rolls of material, comprising:-

: Maximum Width of material: 340mm

: Maximum reel Diameter: 800mm

: Maximum Weight of reel: 150Kgs

: Maximum Speed 75 Mtr/min

: Lifting Arms (Actuator Controlled)

: Air Shaft with Inflator Gun

: Reel Diameter Sensor to maintain tension

: Splicing Table

: Motorised Out feed Nip

: Laser Controlled Loop

: 2 Emergency Stop Buttons

If you would like more information on this product, please Contact Us

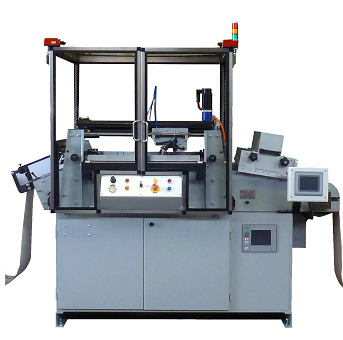

Newfoil NM Hot Foil Stamping and Die Cutting Stations

The number of hot foil stamping, embossing and die-cutting stations and their position in the machine line can be specified to meet the customer’s requirements.

: Maximum Width of material: 340mm

: 310mm x 270mm Printing and Die-Cutting area

: NM5534 – 2 x Print/Emboss* & 1 x Cut Stations

: NM3534 – 1 x Print/Emboss* & 1 x Cut Stations

: NMSSH – 1 x Print/Emboss* Station

: NMTTC – 1 x Cut Station

* Embossing has never been easier when using the Newfoil “QUICK SET” embossing unit.

The new system makes set-up and adjustment of embossing and combination tooling quick and easy.

If you would like more information on this product, please Contact Us

Newfoil’s UV. Flat Screen Unit.

Important Characteristics:

Maximum web width – 340mm (13, 3/8″)

Maximum print width – 330mm (13″)

Maximum Repeat – 508mm (20″)

Minimum Repeat – 208mm (8, 3/16″)

DRYING UNIT:

Fully automatic U.V. dryer

SPEED:

5 to 15 metres per minute (16 to 49 feet per min.)

WEB TENSION:

Adjustable vacuum tension drum.

Laser controlled web feed

WEB GUIDING:

Mechanical web edge guide

Servo web re-registration system with photocell control.

View video Here.

If you would like more information on this product, please Contact Us

Newfoil SF330 Flexo Printing Unit

Important Characteristics:

: Fully automatic U.V. dryer.

: Adjustable vacuum tension drum.

: Web re-register for pre-printed webs.

: Maximum print width – 330mm (13″).

: Maximum print repeat – 508mm (20″).

This versatile flexo unit has the ability to tint coat and print a blank material stock as well as overprint a coloured, varnished or spot varnished image in register to a pre-printed web.

(The number of print stations to be specified by the customer)

If you would like more information on this product, please Contact Us

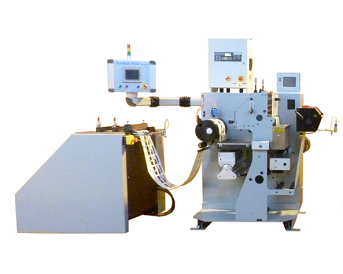

Newfoil NM Rewind and Finishing Unit.

Important Characteristics:

: Maximum web width – 340mm.

: Maximum label rewind diameter – 400mm.

: Maximum waste rewind diameter – 600mm.

: Two label rewinds with pneumatic core holders.

: waste stripping unit with pneumatic core holder and lay-on roller).

A free standing, large capacity finishing and rewind unit, designed to accept our range of slitting, sheeting, punching and stacking options.

If you would like more information on this product, please Contact Us

Tony Davies

May 28, 2019

Converting equipment