Options

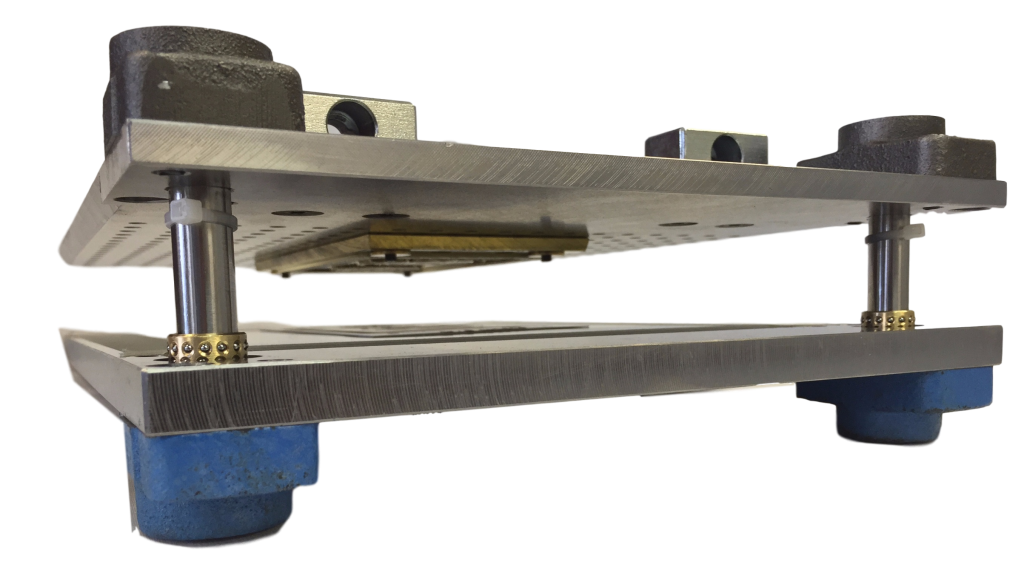

The Quick Set Embossing System

The embossing die set can be used in any print/cut station on our 500 series or servo range of machines and can be heated for use with standard hot foil.

The embossing die set can be used in any print/cut station on our 500 series or servo range of machines and can be heated for use with standard hot foil.

The die set enables you to adjust the tool and counter force in an ‘x – y’ or rotational direction allowing the tool to be moved in to register with a pre-printed web, whilst keeping alignment between the tool and counter force.

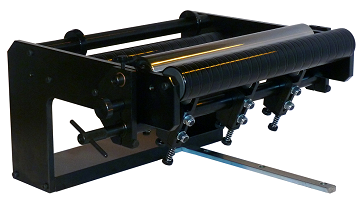

The rotary slitting/scorer unit is a self contained bolt on assembly. Equipped as standard with three cutter holder assemblies. The minimum distance between cuts is 22mm (7/8″), edge trimming is possible to a maximum of 5mm (3/16″) dependent on the material. Cutting pressure and depth of cut are independently adjustable. The cutting wheel is brought to bear on the anvil roller at a tangent, giving very precise and sensitive adjustment. Wheels are disposable and easily replaced. A variety of different wheels are available for perforating, creasing etc.

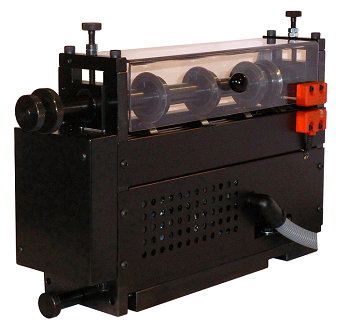

Rotary Scissor Slitter

The rotary slitting unit is a self contained bolt on assembly. Equipped as standard with four pairs of slitting wheels, these are adjustable across the web for slitting and edge trimming. The bottom cutters are powered by an A.C. electric motor/gearbox located within the assembly. The scissors action gives clean precise cuts on paper and most synthetic materials. The minimum distance between cuts is 19mm, edge trimming is possible to a maximum of 4mm; dependent on the material.

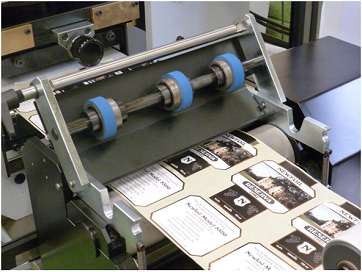

Web Draw Tyre Kit

Replaces the standard full width nip roller assembly when producing embossed labels or when full contact across the web is not desired.

Dependent on model the kit comprises of two – three 20mm wide nip tyres mounted on twin ball bearings with a set of positioning collars.

A special shaft is supplied to allow the rollers to slide and locked into position.

.

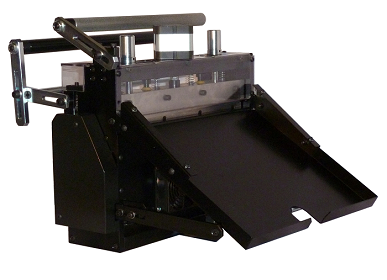

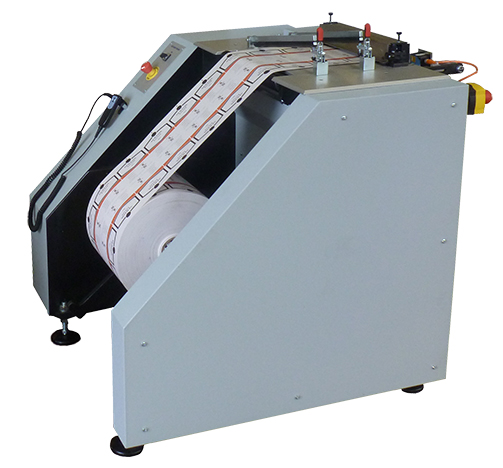

Sheeter

This Sheeting Unit gives the option to convert from roll to sheet, single or multiple impressions. The provision for stripping die-cut labels prior to sheeting is incorporated. The sheeter blades are pneumatically operated and made from high speed steel for long life.

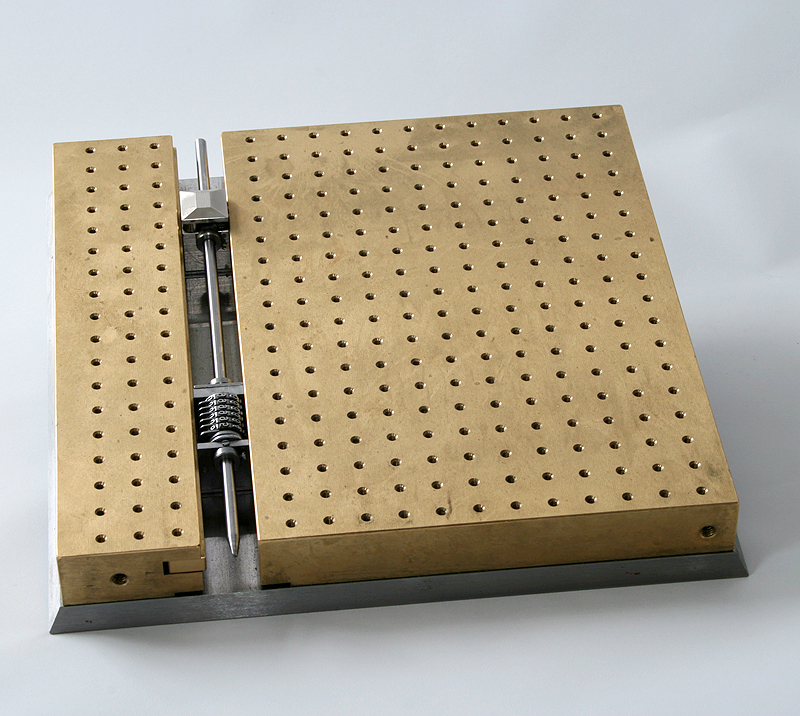

Numbering Head Chase

The numbering boxes supplied are all steel units fitted with hardened steel wheels, which are chrome finished for hot foil use. Six wheels are fitted and normally down counting, standard character size is 4mm (18pt), other sizes in the range of 2mm to 6mm high are available. Operation is by remote plunger connected to the numbering unit by a drive shaft.

All numbering units allow the simultaneous use of 16 gauge etched dies and a matrix of M3 tapped holes to allow easy attachments, the hole centers are the same pitch as the standard gauge plates.

Variable Data Unwind Unit

The addition of a high quality, high speed inkjet or thermal printer enables variable data and graphics function e.g. barcode printing. The printer is mounted on a special unwind unit which includes the web handling and interface connections to the Newfoil machine.

The main drive of the Newfoil machine is modified to enable control from the unwind, this enables the two printing machines to run at optimum speed. The inkjet or thermal printer is used in conjunction with a Personal Computer and can be used as a stand alone printer.

[Back to top]

Magnetic Die Holder Plate

Will allow the use of magnetic shim die-cutting tools on flat bed Newfoil hot foil printing and die-cutting machines.

The magnetic plate is designed to interchange with the standard Newfoil die holding plate and 12mm high steel rule cutter with the minimum of adjustment to the cutting depth.

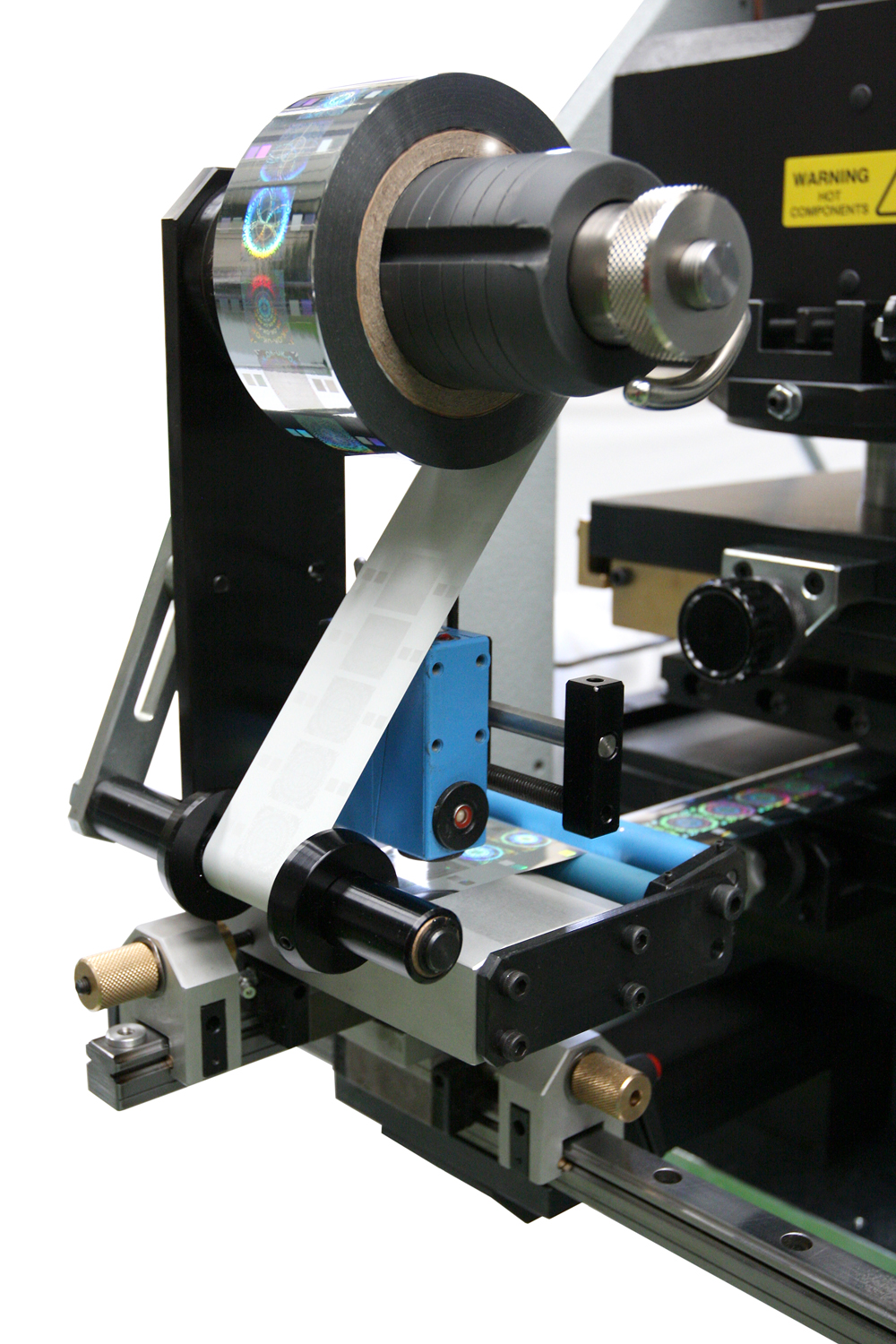

The New Hologram Re-Registration Unit MKIV

The MKIV hologram attachment can be fitted as standard or retro fitted to the new Newfoil 500 Servo series Hot foil label printing and converting equipment. It has been specially developed for use with the servo series of machines.

Holograms are increasingly used for product identification and security purposes within the pharmacutical, electronic and automotive industries.

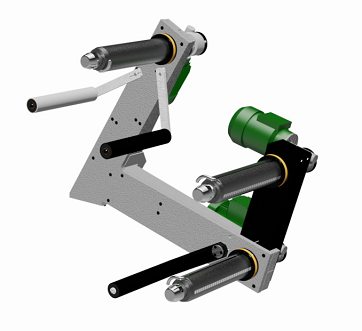

Third Rewind Arm

The third rewind arm is an option to allow slit material to be re-wound in a staggered formation onto two independantly driven mandrels, making for easier setup and unloading.

Rotation direction is selected from the HMI touch screen control panel.

Heavy Duty Unwind

: Maximum Width of material: 340mm

: Maximum reel Diameter: 800mm

: Maximum Weight of reel: 150Kgs

: Maximum Speed 75 Mtr/min

: Lifting Arms (Actuator Controlled)

: Air Shaft with Inflator Gun

: Reel Diameter Sensor to maintain tension

: Splicing Table

: Motorised Out feed Nip

: Laser Controlled Loop

: 2 Emergency Stop Buttons

[Back to top]